Modeling and simulation methods explore the physics behind a phenomenon and are often accompanied by powerful mathematics. These methods provide us with the ability to know the subject and inspire us to create useful engineering artifacts. A phenomenon of particular interest is the processing and properties of natural materials [1, 2]. By knowing this subject, we hope to be inspired by nature to create next-generation lightweight, high-strength and high-toughness engineering materials.

Natural materials, which have risen from billions of years of evolution, have developed unique characteristics. The fabrication of natural materials is very efficient and sustainable through a bottom-up self-assembly at ambient temperature and pressure. Among all the bio-inspiring processing methods to emulate the design and assembly principles learned from nature, freeze casting is a promising approach to form various bio-inspired structural materials with excellent microstructural control.

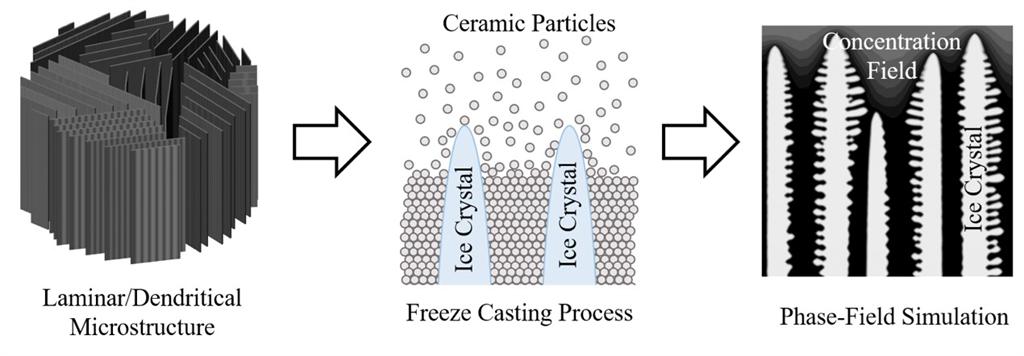

Freeze casting belongs to a broad field of freezing colloids, a phenomenon often observed and encountered in nature or in technology applications. Sea ice, freezing soils (frost heave) and the making of frozen dessert and ice cream are some of the widely known examples of freezing colloids. Freeze casting exploits the solidification (freezing) behavior of a solvent to form controllably porous ceramics, metals or polymers. By freezing a colloidal suspension, ice crystals nucleate on one side of the slurry and grow along with the external and controllable temperature gradient. The ice crystals redistribute the suspended particles as they grow within the slurry, effectively templating the desirable porous microstructure.

A study by Chuin-Shan Chen et al. [1] presents probably the first working phase-field model of a freezing colloidal suspension. As it is not computationally feasible to explicitly trace the motion of each colloidal particle by molecular dynamics or coarse-grained particle simulation, the modeling and simulation of the interactions of colloidal particles with a moving solidification interface are simplified in this work. Under the assumption that colloidal particles can be represented by a continuous concentration field, the interfacial condition of mass conservation, the Gibbs-Thomson condition, and particle segregation can be naturally included in the model.

A major difficulty in modeling a sharp interface is the stability of the associated partial differential equations. To this end, a free energy is constructed, and a diffusive phase-field model is derived. The finite element method with mesh adaption is developed. The proposed phase-field model allows us to track the evolving interfaces during the solidification process and predict the dendritic and laminar microstructures often seen in freeze casting (Figures 1 and 2).

The simulated results not only agree well with the experimental measurements but also enable the exploration of the influence of different processing variables on the evolving morphology of the microstructures. These morphologies include the microstructural patterns from different initial concentrations and different freezing front velocities controlled by the external temperature gradient. As we now have access to 3D evolving architectures through micro-computed tomography (microCT), the proposed model opens a gateway for designing next-generation bio-inspired structural materials with freeze casting.

Figure 1. Modeling and simulation of the laminar and dendritical microstructure by the freeze-casting process. From left to right: laminar and dendritical microstructure, ice crystals redistribute the suspended particles as they grow within the slurry and the phase-field simulation.

Figure 2. Phase-field method using the adaptive finite element method. The refinement of extremely small meshes resolves the dendritical interface in the phase-field method.

References

1.Huang, T., Huang, T., Lin, Y., Chang, C., Chen, P., Chang, S., & Chen, C. (2018). Phase‐Field Modeling of Microstructural Evolution by Freeze‐Casting. Advanced Engineering Materials,20(3). doi:10.1002/adem.201700343.

榮登 Very Important Paper, Cover Image, 榮登期刊封面。

2.Huang, T., Chen, C., & Chang, S. (2018). Microcrack Patterns Control the Mechanical Strength in the Biocomposites. Materials and Design, 140, 505-515. doi:10.1016/j.matdes.2017.12.015.