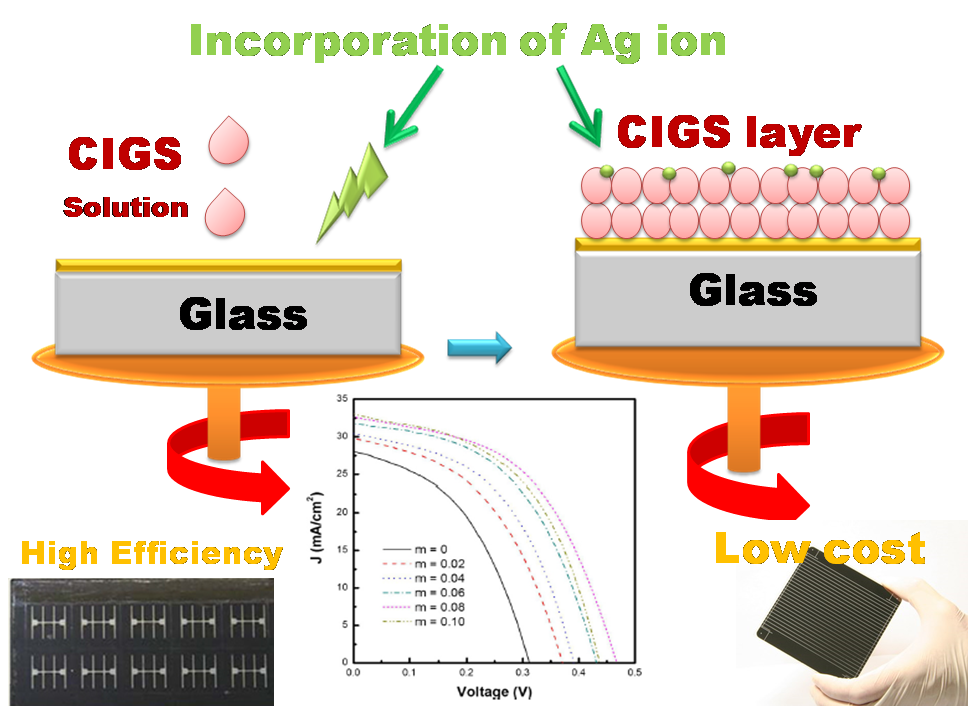

Figure 1. Schematic diagram of a CIGS solar cell.

It is well known that the light scattering caused by the surface texture of a conventional solar cell may enhance the trapping of light absorbed by the semiconductor. This is due to the associated increase in the surface area, which helps to increase the rate of minority carrier recombination on the surface regions. Many studies have been performed using metal-nanoparticle plasmonics to improve the efficiency of solar cells, and the most straightforward way to enhance solar cell efficiency is the incorporation of metal nanoparticles on the surface of the solar cell. This approach does not alter the fabrication of solar cells or form any other recombination centres. The design parameters of metal nanoparticles, including the nanoparticle size and shape, the dielectric environment and the stacked semiconductor layers, strongly influence solar cell performance. The incorporation of silver ions (Ag+) into CIGS absorbers to form (Ag, Cu)(In, Ga)Se2 (ACIGS) absorbers has also been studied. ACIGS solar cells exhibit wide band gaps and high efficiency values. The microstructures of absorbers considerably influence the performance of CIGS-based solar cells.

CIGS absorber layers are customarily fabricated via the co-evaporation method or sputtering techniques. Although these methods are useful in terms of controlling the grading type of gallium ion contents, these methods require expensive high-vacuum accessories. Therefore, to lower manufacturing costs, nonvacuum solution-coating approaches have been developed for preparing CIGS solar cells. However, the microstructures and photovoltaic properties of ACIGS solar cells warrant detailed investigation. Until now, ACIGS absorbers have generally been prepared via vacuum processes, such as the co-evaporation process and the sputtering process. To overcome the shortcomings of high cost and low material utilization in vacuum processes, the development of nonvacuum processes for preparing ACIGS absorbers is essential. One research group has also previously reported the effects of selenization temperatures on the crystalline phases and the microstructures of ACIGS films.

Figure 2. Schematic representation of spin coating and corresponding Ag+ ions incorporation.

Therefore, in the present research, ACIGS films with various Ag+ ion contents were prepared on Mo-coated soda-lime glass via the spin-coating process followed by the selenization process. The phases formed during selenization of the prepared films were analyzed. The microstructures and low-temperature photoluminescence spectra were examined to elucidate the properties of the prepared films. The photovoltaic properties of solar devices fabricated using the obtained films were characterized and investigated in detail. Increasing the Ag+ ion content increased the lattice parameters of the chalcopyrite structure. The band gaps of the prepared ACIGS films were considerably increased, thereby increasing the open-circuit voltage (Voc) of the solar cells. As the Ag+ ion content increased, the microstructures of the ACIGS films became densified because the (Cu, Ag)2 formed in the alloy phase with a low melting point, which facilitated liquid-phase sintering. The evaporation of selenium species was correspondingly suppressed in the films during selenization, thereby reducing the selenium vacancies. The improvement in the microstructures and defects of the ACIGS films increased the short-circuit current (Jsc) and fill factor of the resulting solar cells. The spectral response of the solar cells was also enhanced remarkably. This study demonstrates that incorporation of Ag+ ions into CIGS films substantially improves the efficiency of the solar cells.

References

1. Chen, F. S., Ma, J. S., Sung, J. C., and Lu, C. H. (2013). Bismuth-ion doped Cu(In,Ga)Se2 thin films: preparation microstructures and electrical properties. Solar Energy Materials and Solar Cells, 124, 166-171. DOI:10.1016/j.solmat.2013.12.023

2. Minemoto, T., Matsui, T., Takakura, H., Hamakawa, Y., Negami, T., Hashimoto, Y., Uenoyama, T., and Kitagawa, M. (2001). Theoretical analysis of the effect of conduction band offset of window/CIS layers on performance of CIS solar cells using device simulation. Solar Energy Materials and Solar Cells, 67(1-4), 83-88. DOI:10.1016/S0927-0248(00)00266-X

3. Liu, W., Wang, X., Li, Y., Geng, Z., Yang, F., and Li, J. (2011). Surface plasmon enhanced GaAs thin film solar cells. Solar Energy Materials and Solar Cells, 95(2), 693–698. DOI:10.1016/j.solmat.2010.10.004

Chung-Hsin Lu

Professor, Department of Chemical Engineering